SignalMAX.NET is a leading international supplier of Telecom Manufacturing Services. We have been designing and producing enclosure, passive termination accessories, fiber optic cables, electrical cables, industrial cables, special cables, electronic cables and cable accessories for 18 years. We invite you to browse „Products“, where you will find in-depth product and technical information.

We have two factories for production.

Cable factory: Phase 2, Dakeng Industrial Park, Guanyuan, Foshan, PRC

Metal CNC / laser cutting factory / mould workshop: HeTaGang Shashui, Songgang town, Foshan, PRC

Our value proposition to clients is based on the scientific and systematic management of product design, production flow and quality control in return of best cost saving for client.

We take reference from recognized Telecom standard., such as, IEEE, TIA / EIA and UL. Our quality control procedures are designed by Hong Kong engineers.

SignalMAX.NET offers you a large and diverse product portfolio combining quality, value, availability and service.

PRODUCT DESIGN SERVICE

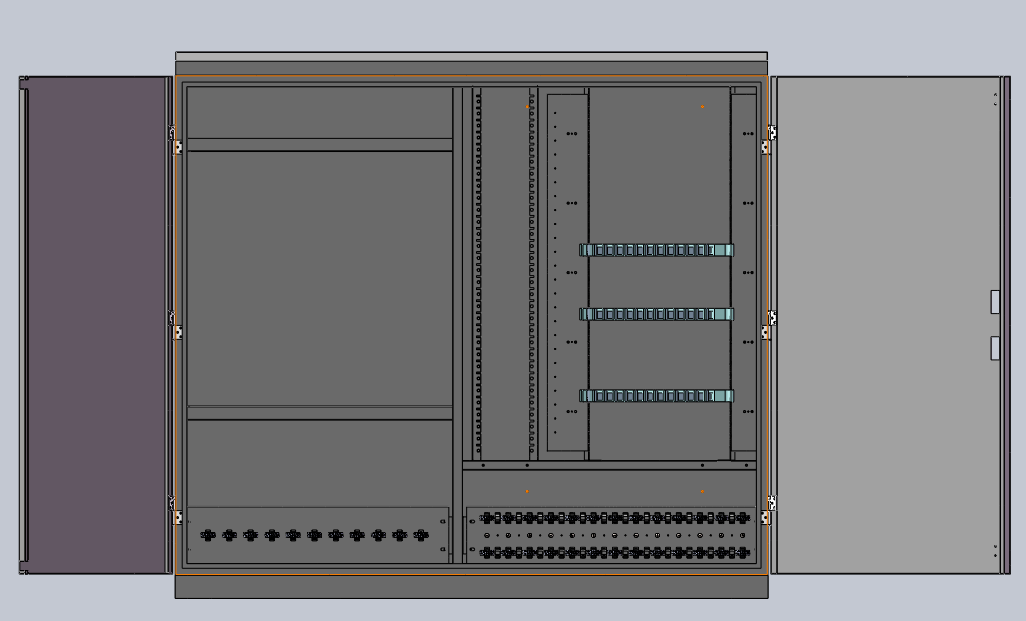

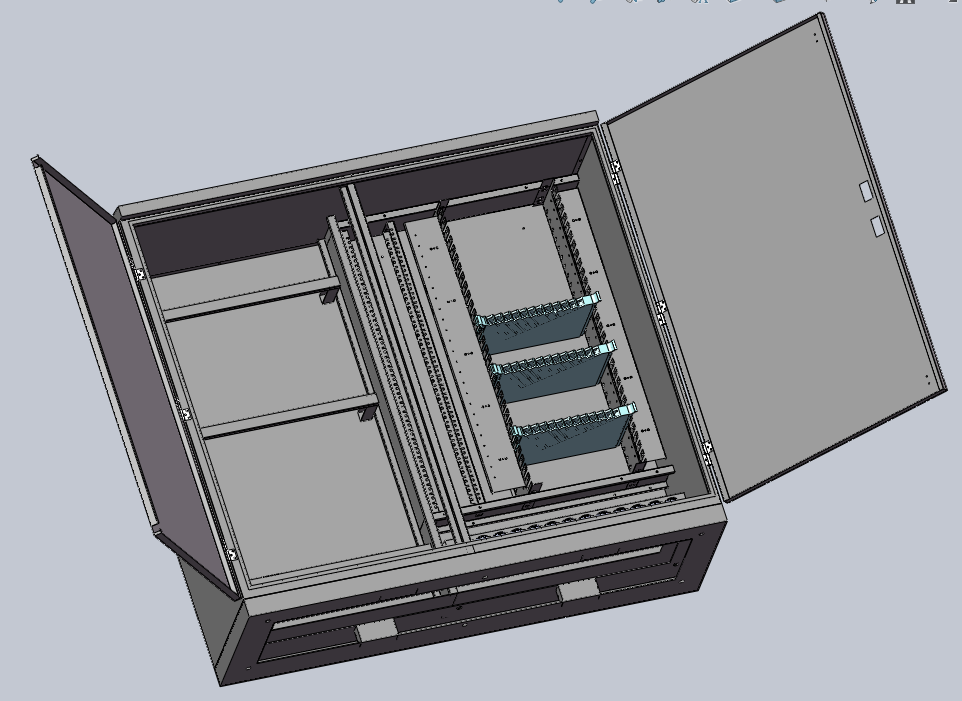

2D or 3D PRODUCT DRAWING.

Signalmax.net engineers could design the outlook, internal design and external modules according to the user requirements. Our unconventional way of design combines with cutting-edge digital technologies that help designers to design virtual prototypes and visualize products in two-dimensional or three-dimensional space. We have more than 18 years‘ experience in collaborating with internet service providers, contractors and system integrators in the world. Our expertise in the telecom industry enables us to design the product in a simple but cost-effective way.

PRODUCT EQUIPMENTS

Our factory in Foshan has several metal processing equipment and machinery. Some of them are imported from Amada in Japan. They create metal cutting, forming, shearing and punching. Thick metal sheets can be processed and then become different shapes. Then, they are processed by our inhouse spraying workshop to complete coating.

Laser cutting machinery directs the output of a high power laser to the materials. We use a motion control system to follow a CNC or G-code of the pattern that results in the delicate cutting of the material without deformation. The laser-cutting process leverages a high-powered laser to burn, melt away or vaporize undesired objects. That results in the cutting with high-quality and surface-finished edge.

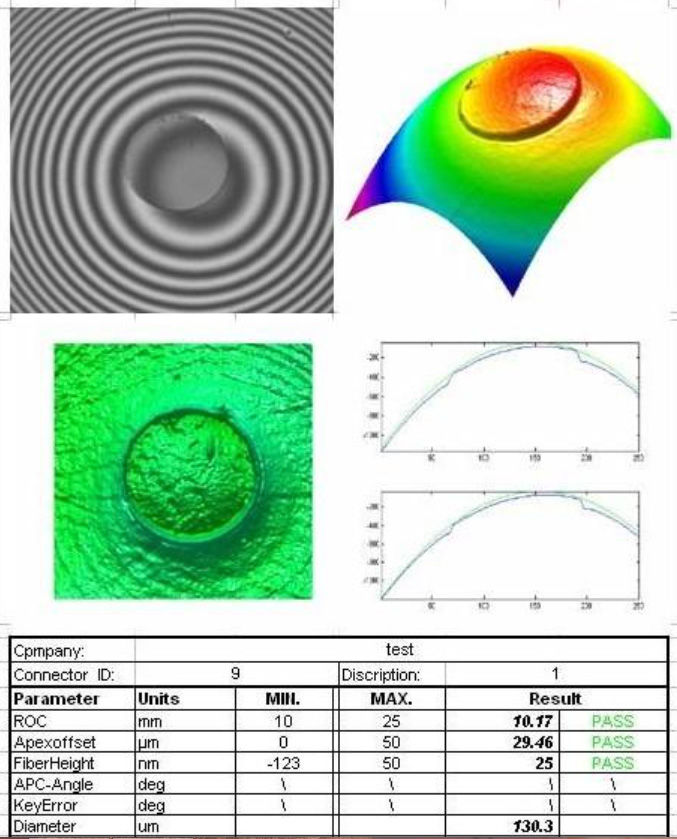

PRODUCT TESTING

We conduct quality assurance (QA) testing during a stage environment, where product designers, engineers and our customers can test the features or functionality of a product before releasing it publicly. Our workshops are equipped with mechanical and electrical testing machines. We can generate the test result during different stage of product development. We test the fiber optics cables and accessories with a visible light source, power meter and optical time domain reflectometer (OTDR).

Besides mechanical testing, our engineers have 20 years experience in low-voltage electrial circuit design and cable developments. We cconduct electrical testing on cables, cable TV products by HP analysizer that provides insertion loss, return loss, isolation and video measurements.

QUALITY CONTROL

Quality control involves testing units and determining if they are within the specifications for the final product. Signalmax.net adopts Total Quality Management (TQM) consists of practices designed to improve the process performance of a company.

Production line is scalable and variable. Our customer service is friendly and responsive.

Please feel free to send enquiry by email to: cs@signalmax.net